Unit Testing Embedded C: On-Target with minunit and Off-Target with MS Test

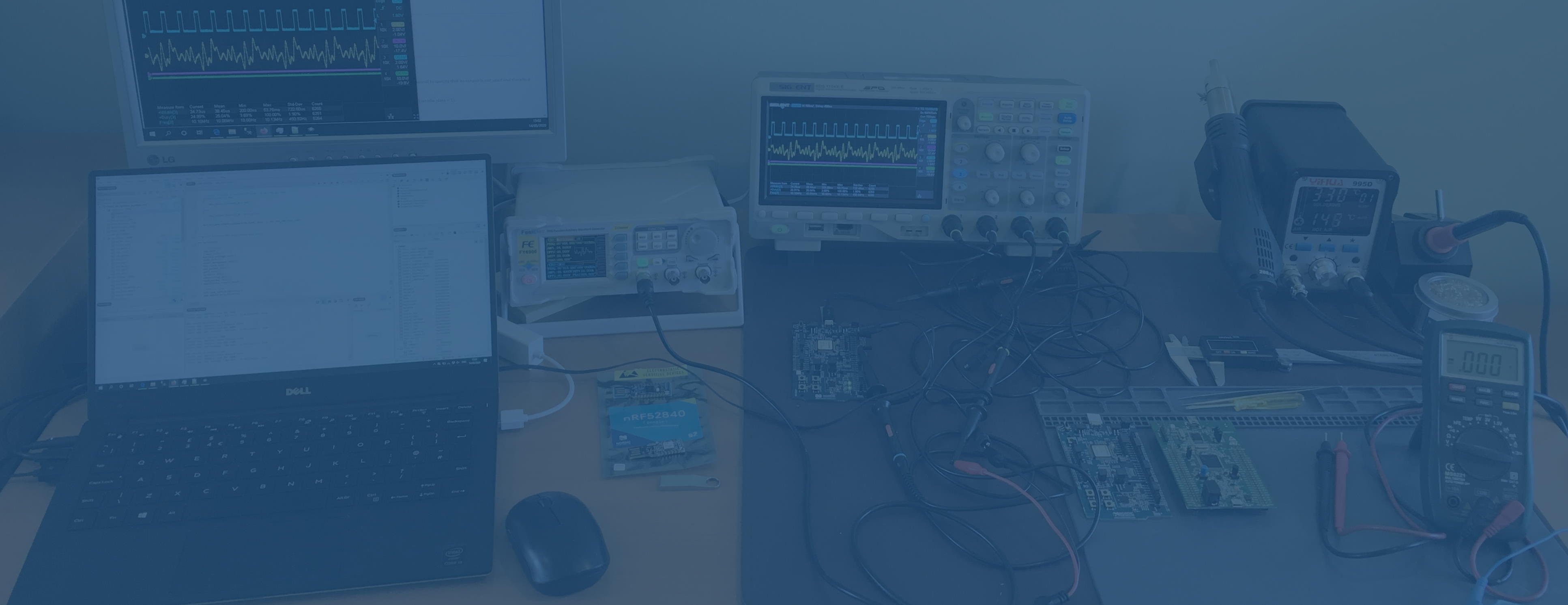

Generally, the advice on unit testing in embedded environments is to run your tests on the PC host rather than on the target device. Whilst I agree that this is the most productive arrangement, there are a variety of reasons for needing to test on the target which can be convincing in certain situation. The technique described here allows for both. Mike Long in his GOTO 2015 presentation Continuous Delivery for Embedded Systems says "Test on your host because that's fast - it's a really fast way to develop. But also test on the target because behaviour can change in different ways, different compilers, different hardware..." Niall Cooling in his talk at the EmbeddedOnlineConference 2020 "How agile is changing the face of embedded software development" says (at 46m) on the gap between testing on the host and the target Things like TDD really are based on testing in the host, and really that's fine but of course we are typically using host compilers like host GCC and of course we know that at the moment this is typically going to be an Intel based processor. So we are compiling for the underlying OS. And it is good for finding a…

Continue reading...